Top 5 Ways How In-House Production Can Make the Difference

In an industry where precision, speed, and quality make all the difference, our fully in-house production process sets us apart. From initial concept through to design, print, and installation, everything happens under one roof in our warehouse based in Huddersfield, UK. This allows our team to deliver stunning lightboxes which our customers have complete confidence in.

1- End-to-end control

At the heart of this approach is quality control. Because we manage every stage internally, our team can maintain absolute oversight of quality and consistency. There’s no waiting on third-party suppliers or chasing multiple contacts to make sure a brief is understood. Instead, every lightbox is crafted to the same high standards, with rigorous quality testing at each stage. For customers, this means fewer errors, faster production, and a final product that looks exactly as envisioned.

2- Customisation, flexibility and speed

That level of control also brings freedom. With in-house production, we can offer true customisation – from unique sizes and shapes to bespoke lighting arrangements and installations. Whether a project calls for a slimline retail display, a large-format museum piece, or a dramatic ceiling-hung structure, our team can adapt quickly. Adjustments are made seamlessly during production and not delayed by depending on external companies. For brands working to tight deadlines or creative briefs, that flexibility is transformative.

3- Cost efficiency

Speed is another major advantage. With design and manufacture working side-by-side, communication is instant and turnaround times are significantly shorter. Projects move from concept to installation without the long lead times often associated with outsourced production. And because we also handle graphics in-house, customers can refresh or replace visuals with ease – reusing the same durable frame and simply updating the printed fabric.

4- Sustainability and futureproofing

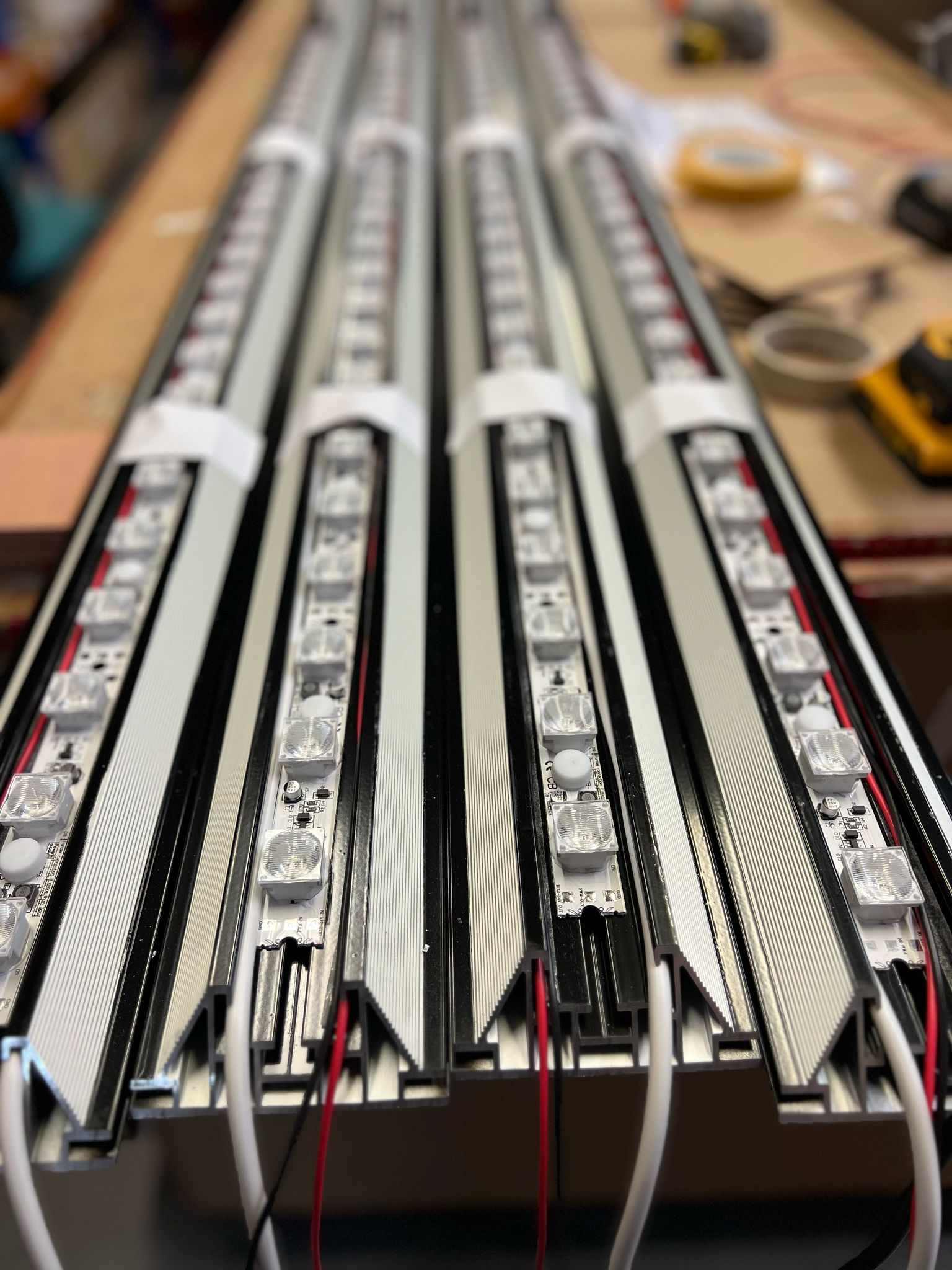

This efficiency doesn’t come at the expense of sustainability. Our production model incorporates eco-friendly materials, energy-efficient LEDs, and recyclable aluminium lightbox and tension frames . By producing locally and eliminating the need to ship parts between multiple suppliers, we also limit our transport emissions. This results in a lightbox that not only looks good but also aligns with the growing demand for environmentally responsible designs across various sectors.

5- Comprehensive, personal customer service

Perhaps most importantly, in-house production creates a single point of accountability. Customers deal with one expert team throughout the entire process – from design discussions to on-site installation. There’s no confusion about who’s responsible for what, and communication remains clear and consistent from day one. That cohesive approach ensures a smoother experience and a more reliable outcome.

Ultimately, this all adds up to a better experience for the end-user, the person standing in front of the display. Our lightboxes deliver high-definition graphics, ultra-bright LED illumination and sleek aluminium profiles that draw the eye and elevate any space. They’re designed to perform, to impress, and to endure.

Interested in working with us?

By keeping production in-house, we don’t just produce lightboxes – we make a promise: of quality, speed, creativity, and care in every project. It’s a commitment that continues to illuminate brands, exhibitions and other various environments across the world. Get in touch to see how we can help transform your vision to life.